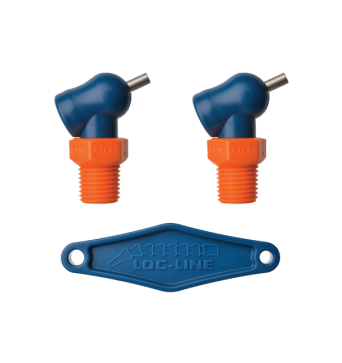

Loc-Line 1/4" (XR Style) High Pressure Turret 1.25" Nozzles - pack of 2 (72083, 79083, 72087, 79087, 72091, 79091, 72095, 79095)

- $74.90

Maximum Pressure: 1,000PSI Never attempt to adjust nozzle while under pressure! Maximum Temperature: 115F (Repeated exposure to this temperature will cause fatigue)

Various packaging sizes/colors available. See "description" below.

Out Of Stock!

This product is out of stock, submit your email and we will update once it restock.

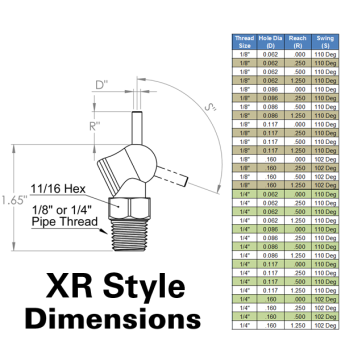

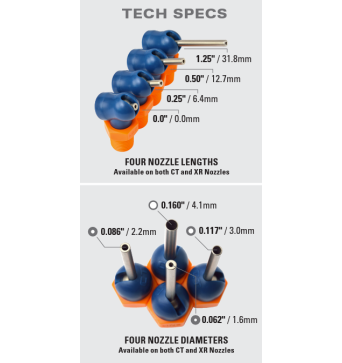

72083 – HPT (XR Style) W/Adj Lever Noz=.062X1.25 Thread= 1/4″ Pack of 2

79083 – HPT (XR Style) W/Adj Lever Noz=.062X1.25 Thread= 1/4″ Pack of 10

72087 – HPT (XR Style) W/Adj Lever Noz=.086X1.25 Thread= 1/4″ Pack of 2

79087 – HPT (XR Style) W/Adj Lever Noz=.086X1.25 Thread= 1/4″ Pack of 10

72091 – HPT (XR Style) W/Adj Lever Noz=.117X1.25 Thread= 1/4″ Pack of 2

79091 – HPT (XR Style) W/Adj Lever Noz=.117X1.25 Thread= 1/4″ Pack of 10

72095 – HPT (XR Style) W/Adj Lever Noz=.160X1.25 Thread= 1/4″ Pack of 2

79095 – HPT (XR Style) W/Adj Lever Noz=.160X1.25 Thread= 1/4″ Pack of 10

Materials and Properties

Maximum Pressure: 1,000PSI

Maximum Temperature: 115F (Repeated exposure to this temperature will cause fatigue)

Never attempt to adjust nozzle while under pressure!

Material: Acetal Copolymer, Stainless Steel

Compatibility:

Yes: Acetone, Alcohol, Ethyl, Greases, Oils, Commercial Dish Detergents, Gasoline, Lacquer, Solvents, Sodium Hydroxide

No: Chlorine, Acids, Ammonium Hydroxide, Bases Strong, Hypochlorite Ion Solutions, Sodium Hypochlorite

Note: Exposure to any chlorine based chemical will cause cracking and product failure!

Please note that all applications have variables and conditions that will affect the maximum working pressures. Testing suitability for your application is always recommended.