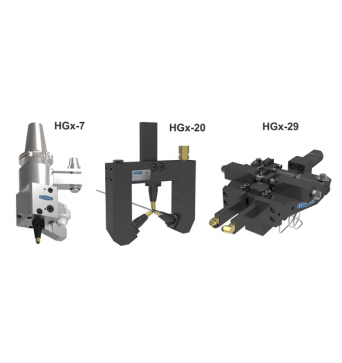

ECOROLL Hydrostatic Tools - HGx-7, HGx-20, HGx-23 and HGx-29

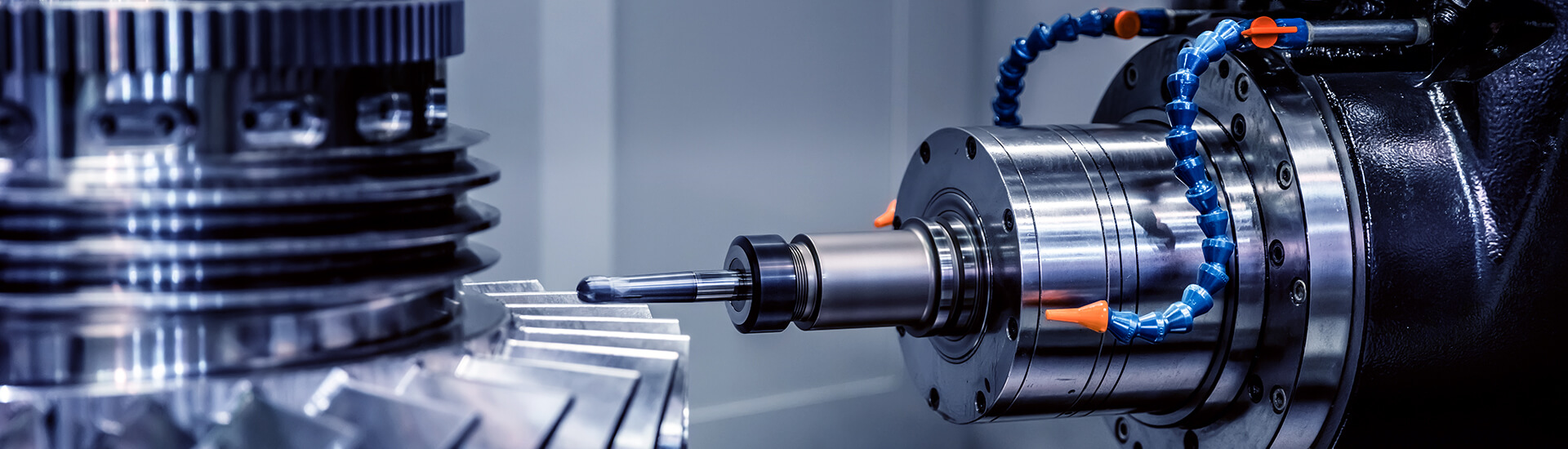

Plane and free-form surfaces as well as outside diameters.

Hydrostatic tools of the ECOROLL HG range are able to roller burnish, deep roll and roller compress the most complex contours and free-form surfaces.

for example, using these tools, piston valves, valves and ball pins are able to be machined.

- Can be used on CNC turning, drilling, milling machines and machining centers, or on conventional machine tools

- Machining of all metallic materials up to a hardness of 65 HRC

- Reduction of machining costs since many subsequent processes such as polishing or lapping are dispensed with

Out Of Stock!

This product is out of stock, submit your email and we will update once it restock.

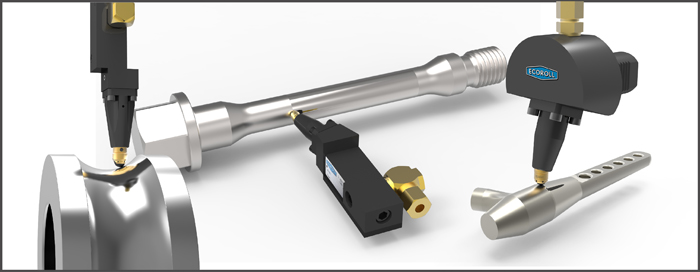

The heart of the HG tools is a special ball of hard material which is hydrostatically mounted in a ball holder. The ball is pressed with a defined rolling pressure against the surface of the work piece by the pressure medium in order to shape it there. The process induces residual compressive stresses into the boundary zone, increases the strength of the material and at the same time smooths the surface.

Note: Tools are listed as HGx-y, where x indicates the ball size and y the design version (e.g. HG6-2 holds a ball with ∅ 6 mm and is designed for machining cylindrical bores).

- Especially designed for external machining of thin cylinders (from 0.05 mm diameter) without additional support of the work piece to prevent flexing of the work piece

- Two static roller elements prevent the work piece from flexing; a third element burnishes or deep rolls the surface

- Provides consistent product quality because the rolling force is dependent on pressure and therefore simple to monitor.

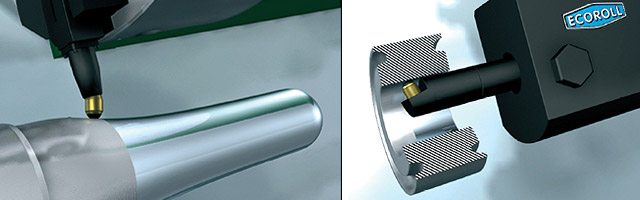

- For machining cylinder and radii contours on axle journals

- The tool rotates the work piece is stationary.

- Provides consistent product quality, because the rolling force is dependent on pressure and therefore simple to monitor.

- For machining both sides of discs and thin-walled components such as turbine blades in a single operation

- For use on conventional and CNC machine tools

- Provides consistent product quality, because the rolling force is dependent on pressure and therefore simple to monitor.

- For roller burnishing and deep rolling plane and free-form surfaces on machining centers and milling machines

- Machining of complex-shaped work pieces which were not able to be machined with the roller burnishing tools previously available

- Integral high-pressure pump; no feed line required