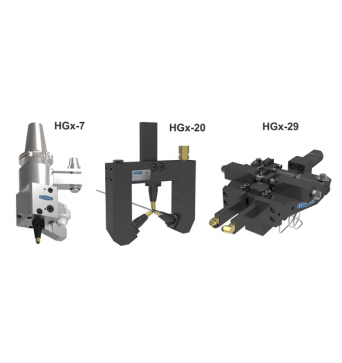

ECOROLL Hydrostatic Tools - HGx-9, HGx-10 and HGx-19

Rotation symmetric surfaces and complex contours.

Hydrostatic tools of the ECOROLL HG range are able to roller burnish, deep roll and roller compress the most complex contours and free-form surfaces.

for example, using these tools, piston valves, valves and ball pins are able to be machined.

- Can be used on CNC turning, drilling, milling machines and machining centers, or on conventional machine tools

- Machining of all metallic materials up to a hardness of 65 HRC

- Reduction of machining costs since many subsequent processes such as polishing or lapping are dispensed with

Out Of Stock!

This product is out of stock, submit your email and we will update once it restock.

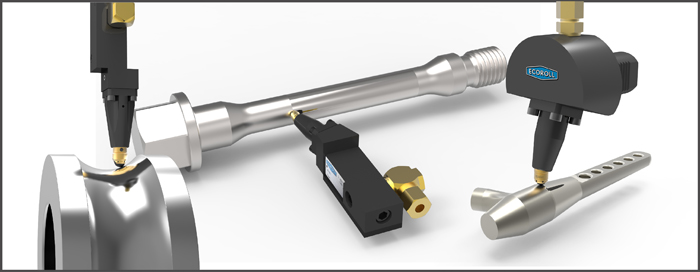

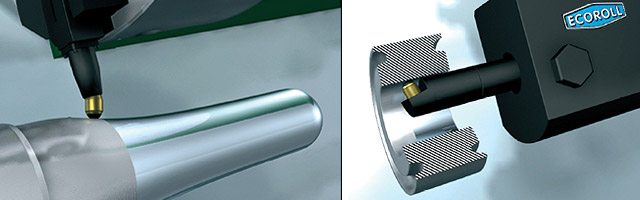

The heart of the HG tools is a special ball of hard material which is hydrostatically mounted in a ball holder. The ball is pressed with a defined rolling pressure against the surface of the work piece by the pressure medium in order to shape it there. The process induces residual compressive stresses into the boundary zone, increases the strength of the material and at the same time smooths the surface.

Note: Tools are listed as HGx-y, where x indicates the ball size and y the design version (e.g. HG6-2 holds a ball with ∅ 6 mm and is designed for machining cylindrical bores).

- For use on conventional and CNC lathes

- Especially designed for roller burnishing of spherical zones and concave fillets

- A pivoting mechanism allows continuous angle adjustment during machining

- Available in right and left-hand versions with standard clamping bar heights

- Machining of all rotation symmetrical components as well as irregular free-formed surfaces

- Rolling force dependent on pressure therefore easy to monitor process with consistent product quality

- Equipped with VDI shank, cylindrical shank, HSK shank or Capto shank

- For use on conventional and CNC lathes

- Clamping bars with heights of 20 - 32 mm

- Available in left and right-hand versions

- Entering angle α = 0 - 90° in 15° graduation