ECOROLL Hydrostatic Tools - Roller Burnishing with Compressed Air and MQL (Minimum Quantity Lubrication)

Roller Burnishing with Compressed Air and MQL (Minimum Quantity Lubrication)

Hydrostatic tools of the ECOROLL HG range are able to roller burnish, deep roll and roller compress the most complex contours and free-form surfaces.

for example, using these tools, piston valves, valves and ball pins are able to be machined.

- Can be used on CNC turning, drilling, milling machines and machining centers, or on conventional machine tools

- Machining of all metallic materials up to a hardness of 65 HRC

- Reduction of machining costs since many subsequent processes such as polishing or lapping are dispensed with

Out Of Stock!

This product is out of stock, submit your email and we will update once it restock.

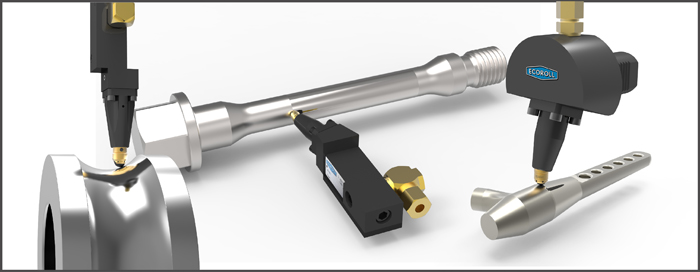

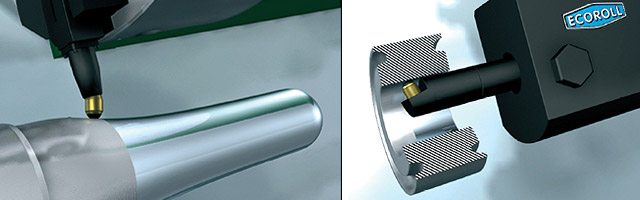

The heart of the HG tools is a special ball of hard material which is hydrostatically mounted in a ball holder. The ball is pressed with a defined rolling pressure against the surface of the work piece by the pressure medium in order to shape it there. The process induces residual compressive stresses into the boundary zone, increases the strength of the material and at the same time smooths the surface.

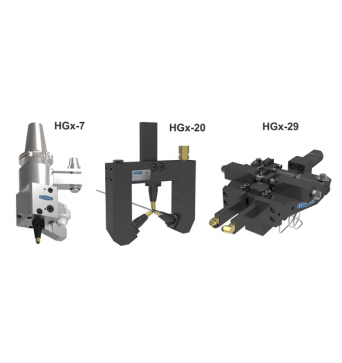

Note: Tools are listed as HGx-y, where x indicates the ball size and y the design version (e.g. HG6-2 holds a ball with ∅ 6 mm and is designed for machining cylindrical bores).

- The ECOROLL Compressed Air System makes ECOROLL tools compatible with MQL-machines.

- Lubricant consumption only amounts to 2 ml/h (0.122 cu. in/h) per ball.

- The machine workspace remains dry and the work piece is covered with a very fine lubricant film which does not contaminate either the machine or the environment.

- The system is applicable for air pressure up to 200 bar (2900 PSI) and therefore, it is suitable for roller burnishing and deep rolling of materials up to 55 HRC.

Depending on the application, air pressure between 20 and 200 bar (290 to 2900 PSI) is required. This pressure is usually not available in most central compressed air networks. Therefore, ECOROLL offers specially tailored compressed-air units for any application: HGL1 For supplying one tool consisting of a compressed air bottle set with two 50l bottles with 300 bar (4350 PSI) filling pressure, a high-pressure MQL system, a control unit for connecting the unit with the CNC machine control for a program-controlled activation and shut-down of compressed air and MQL. HGL2 For supplying a machine with multiple tools consisting of an air compressor with 300 bar (4350 PSI), acoustic insulation, a 50l storage bottle, a control unit for connecting the unit with the CNC machine control for a program-controlled activation and shut-down of compressed air and MQL. This unit is also suitable for fully automated operation.